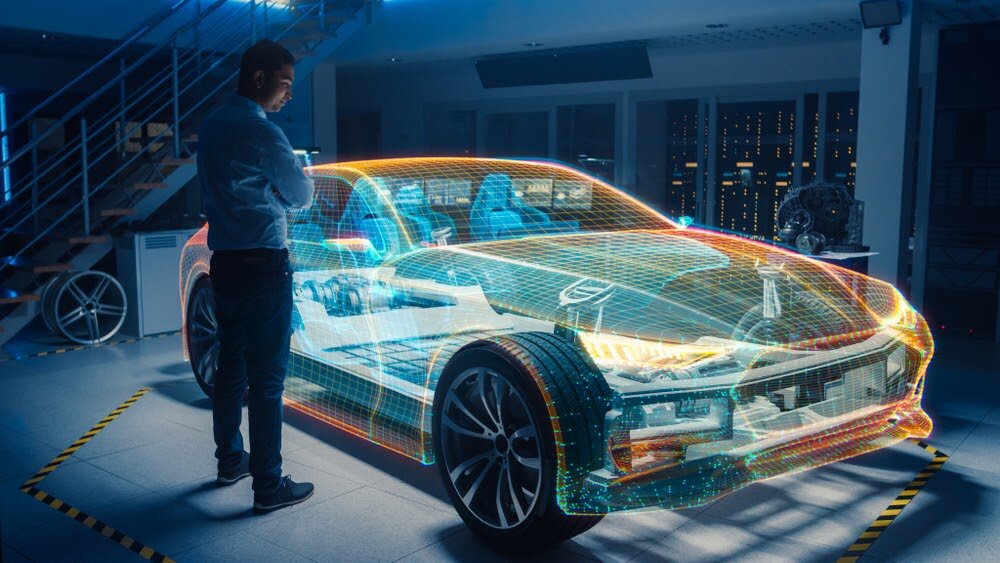

As the industry approaches a 12-figure valuation, one auto manufacturer has taken their brand to the next level with virtual reality technology. Ford recently unveiled the image of a groundbreaking new race car, which was designed entirely using virtual reality.

This 3D design method is providing auto brands with hyper-realistic detailing, improved tactile response, and enhanced blueprint imaging.

Read on to learn how Ford has used virtual reality to revolutionize the design and prototyping phase of automobile production.

Technician training and support

Worker education and training was another aspect of the auto manufacturing process that was greatly impacted by the pandemic. Certain employees who depend on three-dimensional visual and tactile elements were able to continue operations, despite telecommuting demands.

Using mobile-friendly VR headsets or 3D visual projections, workers were able to attend courses, seminars, and training sessions which incorporated realistic exercises with practical applications.

Hands-on professionals can only apply so many skills with videos and images alone. Virtual reality programs make it possible to create cloud-based digital scenarios for virtually every step in the car manufacturing process.

This is also another area where car brands can cut costs, since virtual reality renders replace the need for a physical vehicle model during the product ideation, design, and testing phases.

Safer manufacturing during COVID-19

Like many other industries across the global workforce, COVID-19 had a significant impact on the automobile industry. Stringent distancing measures and regulations for commercial businesses put standard operations on halt for most car companies.

Using virtual reality to design and produce cars allowed employees to effectively work remotely. By maintaining timelines for prototype development, marketing, and distribution, Ford is one of the companies that was able to thrive in spite of the market downturn.

For example, Ford technicians used proprietary VR software to complete the Mustang Mach-E while working from home. This technology gave designers, engineers, and quality control specialists the ability to complete their work remotely, allowing offsite teams to reach production quotas and deadlines successfully.

Virtual reality technology has also made strides for innovation and product development. By simplifying analysis and collaboration processes during the COVID-19 lockdown, Ford used virtual reality headsets for:

- 3D modeling

- Computer-aided designing

- Digital sketching

- Virtual environment generation

Safety is paramount in a time like this, and community health parameters largely outweigh product demand and profitability across the global marketplace. Ford is one auto manufacturer that was able to simultaneously reduce physical contact and streamline the digital design process using virtual reality systems.

Increased level of control during initial design phase

If there’s one thing that can tank the production of a great product, it’s poor communication. In order for something as intricate as a high-performance sports car to successfully reach the last stage of development, everyone involved needs to be on the same page every step of the way.

Detailed 3D diagrams, secure cloud-based file sharing, and mobile-friendly syncing capabilities are making it easier than ever for remote workers to virtually design, test, and analyze new vehicles from any location.

AR/VR-enabled mobile devices and interactive projections give each user the ability to move, rotate, magnify, or expand individual car parts from every angle of the interior, exterior, and frame.

Virtual reality makes it easier for every worker to access information, graphics, and valuable updates regarding the project. The same technology simplifies internal communications by rendering every aspect of the vehicle in a completely digital, cloud-hosted environment.

While this development made it easier for Ford to sustain operations during the pandemic, virtual reality tech will undoubtedly become a mainstay in the automotive industry.

Reduced cost and time spent on prototype development

When using physical prototypes and clay modeling to create a new vehicle, it can take weeks for just one model to come to fruition. Virtual reality allows technicians to complete the same steps digitally in a fraction of the time, reducing the production life cycle to just a few days.

Requiring less time for the creation of each model allows internal and remote teams to allocate their time to other projections. Or, companies can cut a considerable chunk out of their budget by reducing spending on:

- Staffing

- Materials

- Operationa

- Leasing space

- Research and development

Using virtual reality instead of physical development techniques, auto companies can potentially cut the time they spend prior to product launch by more than 20 percent. Unsurprisingly, this can directly translate to a significant reduction in cost almost immediately following system adoption.

As with any company, it’s in the best interest of every auto manufacturer to cut costs and maximize innovation anyway they can. This is especially true when considering the competitiveness of the auto market AND the economic strain of a global pandemic. Scalability and growth is paramount in the current sink or swim environment.

Ford breaks barriers in performance and ingenuity

This industry-changing event was broadcast live to viewers, giving consumers a first-hand look at the process. Ford chose to use a top-performing speed machine as an example, while also appealing to the alternative energy market with an all-electric fuel system.

It’s no secret that Ford sought to make history by dropping the digitally built Mach-E on their growing audience. Innovators who were responsible for the construction and application of VR to production speed, accuracy, and advertising optimization have managed to disrupt the downward trajectory of an entire industry.

Despite being in the midst of one of the most significant economic downturns in American history, Ford’s stocks have risen during the summer slump. This shift in the company’s growth potential shows that it’s still possible to grow and thrive in less-than-favorable commercial circumstances.

Faster launch time and production

By preventing the same pitfalls that caused other auto manufacturers to halt production during the pandemic, Ford was able to exceed industry expectionations by a landslide.

While Ford does own a dedicated VR lab for testing and product development, they’ve successfully moved similar technology offsite. Now, workers can view digital models virtually from their mobile phone, tablet, or desktop computer at home.

Improving the seamlessness of the early stages in the product development process gave Ford the ability to reduce costs and save time sooner than previous methods allowed. This gave them the support they needed to build a brand new unit collaboratively without the use of a physical manufacturing location.

One of the primary inhibitors to corporate profits during the COVID-19 lockdown was the brand’s inability to produce or distribute their products. Showrooms closed, workers were sent home, and production stopped for many brands as they tried to navigate regulations that changed by the hour.

Using virtual reality to bridge these gaps, Ford continued to test, assess, and work out bugs that were found in an entirely digital environment. As a result of these simplifications throughout the critical beginning stages of production, this auto manufacturer made history and was able to release their newest high-performance race car in record time.

Streamlined shopping experience and enhanced marketing

Although virtual reality was used primarily during the first phases of the car’s production, VR also improved Ford’s marketing efforts in a few different ways.

From creating an immersive virtual showroom shopping experience to allowing consumers to tour their prospective purchase from home, VR is making the automotive industry more accessible for everyone.

As a result of the ongoing health crisis, consumers are becoming accustomed to shopping online for everything from groceries to homes to – you guessed it – automobiles. This trend is expected to outlast the pandemic, which will change the way we all interact with consumer products.

Virtual reality is giving every level of consumer a birds-eye view of their new investment, which gives the buyer more independence during their search. Having more customization and control over their purchase gives casual and committed shoppers a much higher level of overall satisfaction regarding the transaction.

By reducing their consumer bounce rate, Ford used virtual reality to turn an exciting new product into a tool for improved client retention and brand recognition.

The application of this technology throughout the rest of the process has allowed car brands like Ford to apply their efforts vertically into areas like:

- Eco-friendly technology

- Alternative fuel methods

- Sustainable manufacturing

- Increased automation

With their compatible at-home VR program, Ford maintained a surprisingly high level of productivity and growth during an incredibly difficult time.

This leading car company has made headlines with their all-electric muscle car, but other brands are following close behind. Cross-functional trailblazers like Bosch and Amazon have shown why virtual reality is a practical investment for nearly every sphere.

By virtually designing an entire vehicle from conception through completion, Ford has changed the way companies and consumers will produce and distribute products. If we learned anything from the buzz around the Mach-E, it’s that virtual reality is here to stay.